FACTORIES

GMP certified in Sep. 2011

Component Factory

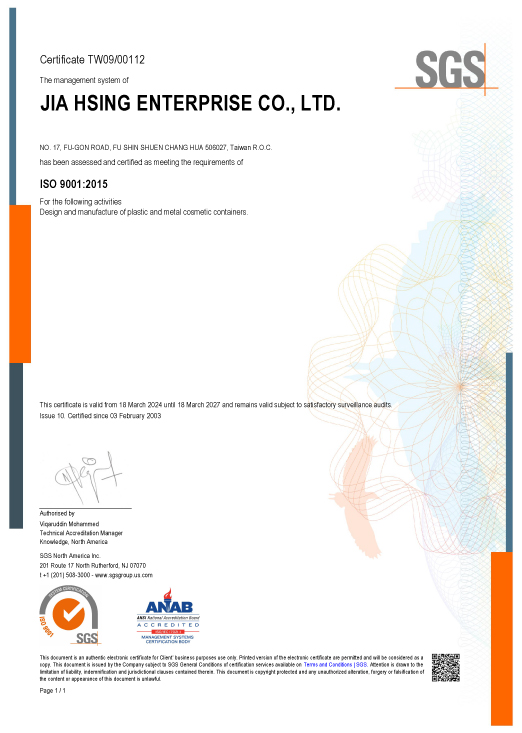

With packaging-manufacture experience over 48 years, Jia Hsing can not only fulfill our customers with the basic process: plastic injection, bottle-molding, and aluminum punching but also provide service of in-house printing, hot stamping, spray coating, and vacuum metallization. Jia Hsing obtained ISO9001 certificate in 2000. All the processes are controlled by a complete quality system. We are confident of supplying customers with perfect products.

Cosmetic Factory

We start turnkey manufacturing form 2003.

In 2007 , a new filling factory with cleanroom of 100 thousand level star using.

We have perfect system and equipment to provide high-quality products including lip gloss, lip balm, powder, mascara , eyeliner , skin care…etc. ISO 17025 certified in 2009. GMP certified in 2011.

We build up our own brand J’shine in 2012.

Our extensive experience ensure that consumers feel excellent quality and service.

In 2007 , a new filling factory with cleanroom of 100 thousand level star using.

We have perfect system and equipment to provide high-quality products including lip gloss, lip balm, powder, mascara , eyeliner , skin care…etc. ISO 17025 certified in 2009. GMP certified in 2011.

We build up our own brand J’shine in 2012.

Our extensive experience ensure that consumers feel excellent quality and service.

R & D

R&D of Component

Jia Hsing’s R&D group is always monitoring the fashion trends. The professional team provides products with innovation and diversification. Customers can choose to develop unique and customized molds. With a constant drive toward perfection in design and utility, Jia Hsing is deeply committed to research and development. Every product produced by Jia Hsing is the result of corporate philosophy and professional staff. Our passion keeps us on the cutting edge of creativity and fashion trends.

Drawing/Design Team

JH has in-house Drawing/ Design team. Professional facility and skill can help customer to develop perfect product design by 2D or 3D drawing. Also can make sure customer to get satisfied product with shortest lead-time.

Mould Testing Team

Independent mould test team has appropriative injection machines to test new moulds, set up manufacture condition, and conduct related testing to make sure new mould can meet JH standard.

Mock-up Team

In-house mock-up team can delivery appearance mock-up or functional mock-up to support customer conducting consumer testing or appearance approval. To avoid any uncertain issue before mould development.

Lab of filling factory

Our labs keep up with the world trend and develop the fashion products. All products comply with FDA and EEC regulations. ISO17025 is certificated in 2009. Through rigorous management and testing the quality can meet market demand. The members of lab are all major in chemistry. With professional experience, we provide customized products and full service to meet the needs of customers.

Formula development

The lab of Jia Hsing provide a wide variety of formula include foundation, press powder, loose powder, baked powder, blush, eye shadow, lip gloss, lipstick, lip balm…etc.

Microbiological monitoring

The microbiological analysis monitored from formulation design to shipping. Besides, the settle plates test monitored weekly in production area y, in accordance with the high standards of CGMP conditions.

Packaging development

Professional packaging design team satisfied the needs of customers. In addition to cosmetic containers, Jia Hsing also design the second packaging and a full services including labeling, store shelf, display box and logistics.

QA of packaging factory

ISO 9001 is certificated in 2000. The pursuit of high quality is the eternal goal of Jia Hsing. The QA department has a variety of necessary inspection equipment. Each process has a complete quality monitoring system. All products are produced under a strict quality management system which can be completely trusted.

QA of filling factory

The inspection items of filling factory include raw material, semi-finished products, finished products, packaging, and manufacturing process. Strict quality inspection is our commitment to customers. With modern scientific instruments such as AA, HPLC the testing items include microbiological analysis, acid value, saponification value, and heavy metal. The ISO17025 is certificated in 2009.

POLICY AND COMMITMENT

Public Greenhouse Gas (GHG) Emission Reduction Declaration

Jia Hsing Corporation has identified climate change as one of the material risks to sustainable business operations and manages it through two key strategic dimensions: mitigation and adaptation. The Company is committed to proactively identifying climate-related risks, enhancing its adaptive capacity, and further analyzing opportunities arising from climate change. In parallel, we continue to strengthen our research and development capabilities, actively invest in green energy, and integrate these efforts with our core expertise in energy management to advance energy conservation and sustainability.

Beginning in 2024, Jiaxing Corporation has initiated the evaluation of methodologies under the Science Based Targets initiative (SBTi) framework to establish near-term emission reduction goals. By 2030, relative to the 2024 baseline year, the Company aims to achieve a 3% reduction in Scope 1 and Scope 2 greenhouse gas emissions.

Beginning in 2024, Jiaxing Corporation has initiated the evaluation of methodologies under the Science Based Targets initiative (SBTi) framework to establish near-term emission reduction goals. By 2030, relative to the 2024 baseline year, the Company aims to achieve a 3% reduction in Scope 1 and Scope 2 greenhouse gas emissions.

Public Statement of Support for the United Nations Global Compact (UNGC) Ten Principles

Respect for human rights and the creation of a dignified working environment are fundamental to both Jiaxing Corporation and our supply chain partners.

Jia Hsing Corporation supports the Universal Declaration of Human Rights (UDHR) and is committed to upholding internationally recognized human rights standards, including the International Bill of Human Rights, the International Labour Organization Declaration on Fundamental Principles and Rights at Work, and the Ten Principles of the United Nations Global Compact (UNGC).

We strictly comply with the laws and regulations of all jurisdictions where we operate and are dedicated to protecting the human rights of all personnel, including full-time employees, contract and temporary workers, and interns. We recognize that addressing human rights challenges in complex supply chains is a shared responsibility across the industry. Therefore, Jia Hsing Corporation expects all supply chain partners to adhere to the same standards.

Jia Hsing Corporation supports the Universal Declaration of Human Rights (UDHR) and is committed to upholding internationally recognized human rights standards, including the International Bill of Human Rights, the International Labour Organization Declaration on Fundamental Principles and Rights at Work, and the Ten Principles of the United Nations Global Compact (UNGC).

We strictly comply with the laws and regulations of all jurisdictions where we operate and are dedicated to protecting the human rights of all personnel, including full-time employees, contract and temporary workers, and interns. We recognize that addressing human rights challenges in complex supply chains is a shared responsibility across the industry. Therefore, Jia Hsing Corporation expects all supply chain partners to adhere to the same standards.